Unlocking Efficiency: How Triplex Pumps Transform Industrial Fluid Management

In the realm of industrial fluid management, the quest for efficiency has led to the emergence of advanced technologies that streamline operations and reduce costs. Among these innovations, the triplex pump stands out as a pivotal component in enhancing fluid handling processes across various sectors. With its unique three-piston configuration, the triplex pump not only offers superior reliability but also significantly boosts performance by delivering a consistent flow rate and high-pressure output. This introduction explores the transformative impact of triplex pumps on industrial applications, shedding light on key benefits, such as improved operational efficiency, reduced maintenance needs, and enhanced environmental sustainability. As industries continue to evolve, understanding how to effectively leverage the capabilities of triplex pumps will be vital for companies aiming to optimize their fluid management systems and stay competitive in an ever-demanding marketplace.

Understanding Triplex Pumps: The Basics of Operation and Design

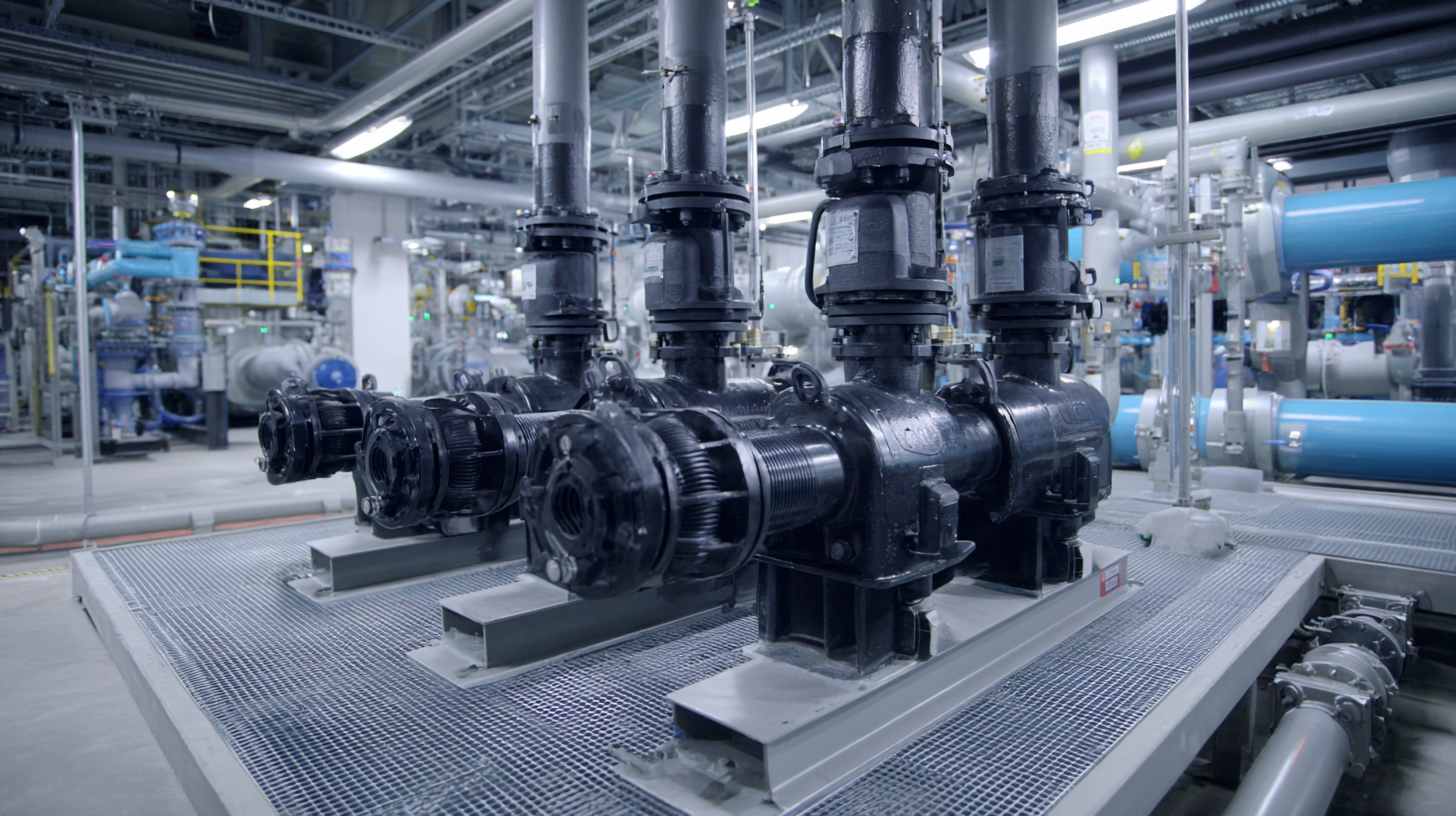

Triplex pumps are essential tools in industrial fluid management, providing enhanced efficiency through their unique design and operation. Unlike traditional pumps, a triplex pump features three pistons working in unison, allowing for a more balanced and continuous flow of fluid. This configuration significantly reduces pulsation, which not only improves the overall system performance but also extends the lifespan of connected equipment. The synchronized action of the pistons ensures that the pump delivers a steady output, making it ideal for applications that require consistent flow rates, such as in oil and gas, water treatment, and chemical processing.

In terms of design, triplex pumps are built with robust materials to withstand high pressures and abrasive fluids, making them particularly suited for demanding industrial environments. The compact design allows for easier integration into existing systems while optimizing space. Furthermore, they often feature a variety of customization options, enabling users to tailor the pump to specific applications and operational requirements. Understanding the fundamentals of how triplex pumps operate and their structural advantages reveals their role in transforming industrial fluid management by enhancing both efficiency and reliability.

Unlocking Efficiency: How Triplex Pumps Transform Industrial Fluid Management

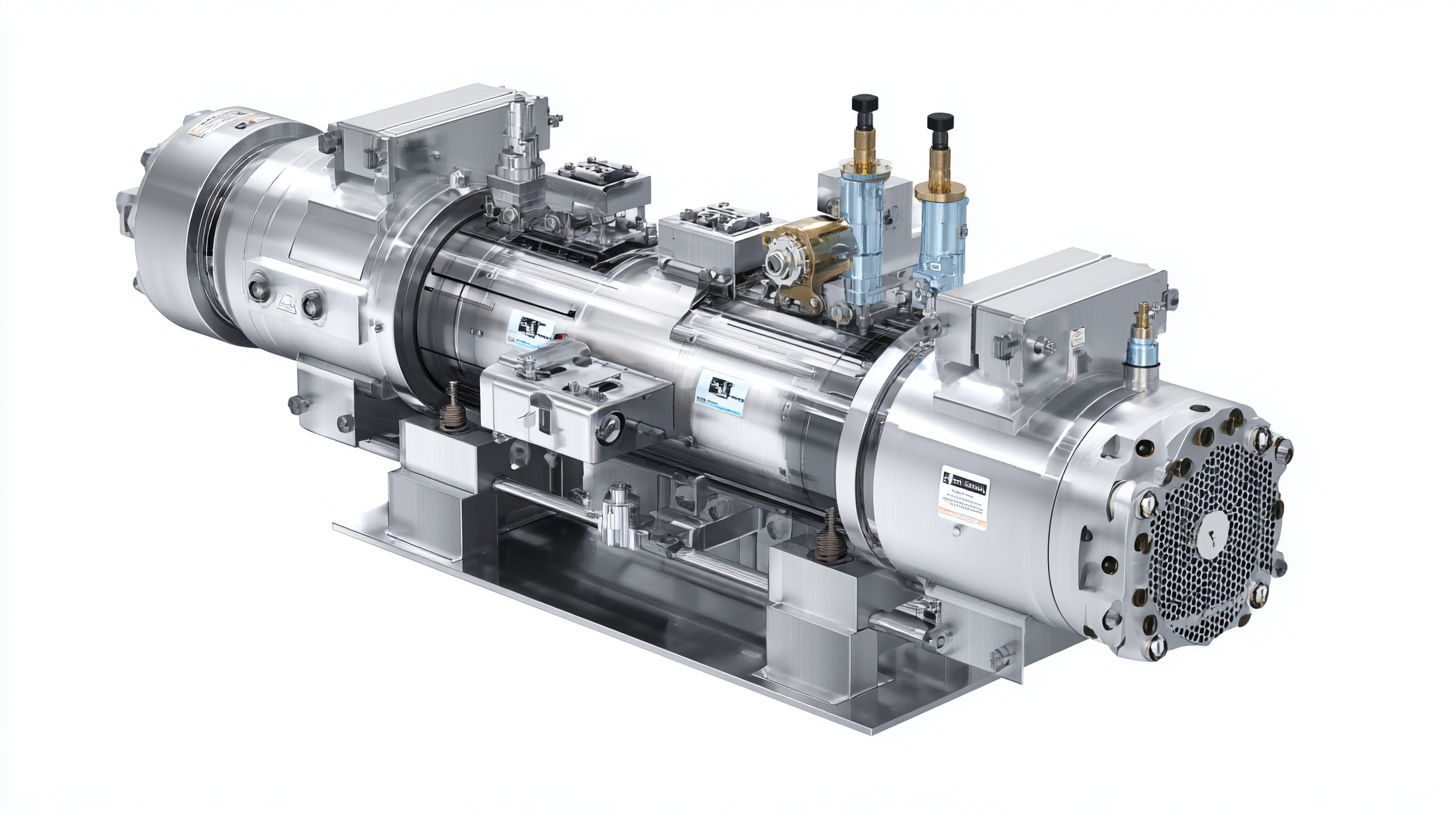

| Dimension | Details |

|---|---|

| Pump Type | Triplex Plunger Pump |

| Number of Plungers | Three |

| Flow Rate | Up to 100 GPM |

| Pressure Range | 100 to 5000 PSI |

| Efficiency | High, with minimal fluid shear |

| Applications | Oil & Gas, Water Treatment, Chemical Processing |

| Maintenance Frequency | Every 1000 hours of operation |

| Design Features | Robust construction, easy access for maintenance |

The Impact of Triplex Pumps on Industrial Fluid Efficiency

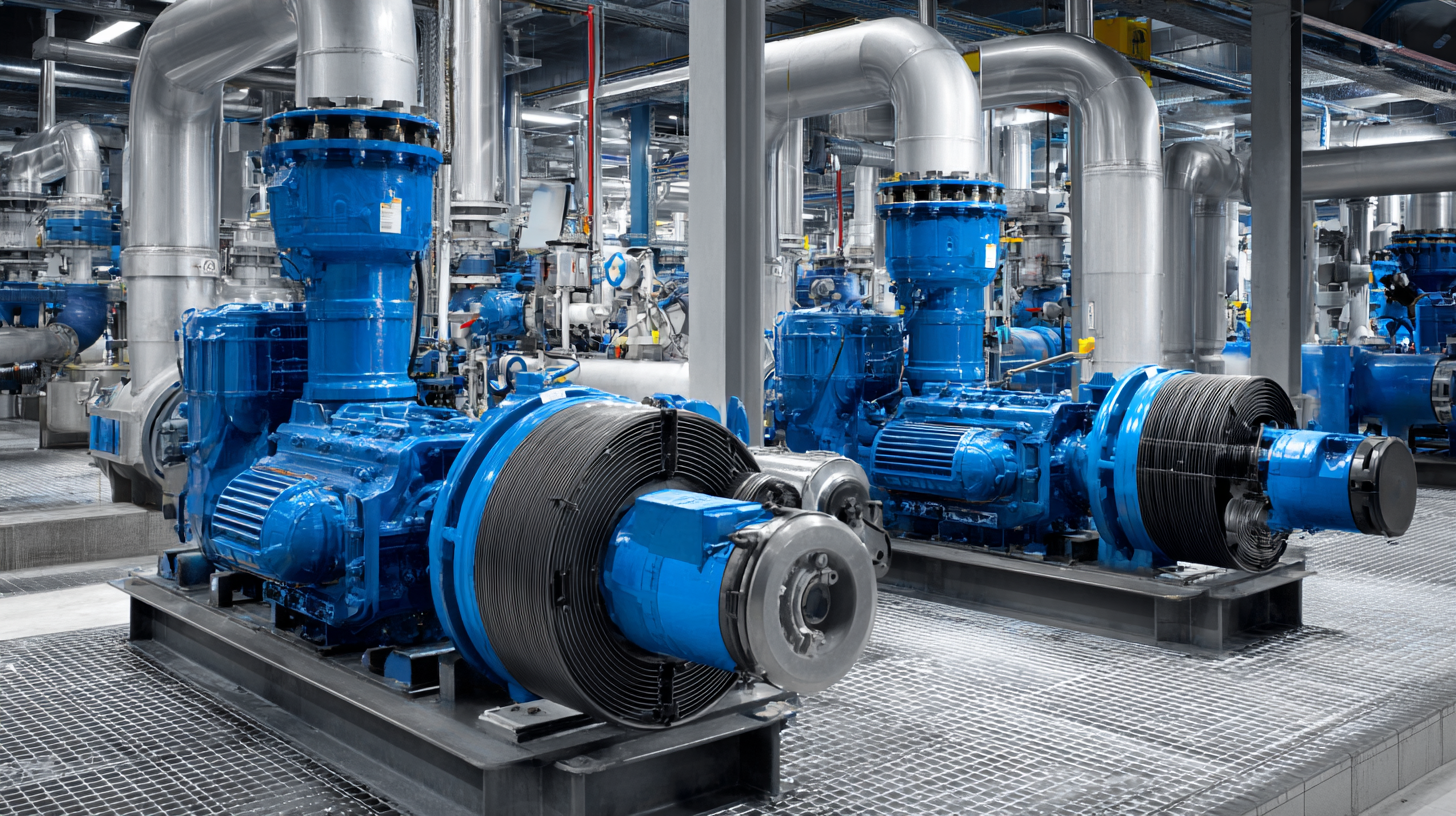

Triplex pumps have revolutionized industrial fluid management by significantly enhancing fluid efficiency across various sectors. According to a report by MarketsandMarkets, the global triplex pump market is expected to grow from $1.2 billion in 2021 to over $1.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 9.1%. This growth is largely driven by the need for more efficient fluid handling solutions that minimize waste and maximize operational effectiveness.

In sectors such as oil and gas, mining, and water treatment, triplex pumps deliver higher pressure and flow rates compared to traditional pumping systems, translating into less downtime and improved productivity. Data from the American Petroleum Institute shows that incorporating triplex pumps can reduce energy consumption by up to 30%, demonstrating their capacity to streamline processes while also promoting sustainability. By enabling precise fluid management, these pumps not only enhance operational efficiency but also contribute to lower operational costs, making them an essential component in modern industrial applications.

Key Advantages of Using Triplex Pumps in Fluid Management Systems

Triplex pumps have emerged as a game changer in industrial fluid management, offering several key advantages that enhance operational efficiency. A significant benefit of using triplex pumps is their ability to maintain constant pressure, which is essential for processes that require precise fluid delivery. According to a report by the American Society of Mechanical Engineers (ASME), consistent pressure in fluid systems can improve overall system performance by up to 15%. This reliability is crucial in industries like oil and gas, where fluctuations in flow can lead to downtime and increased operational costs.

Triplex pumps have emerged as a game changer in industrial fluid management, offering several key advantages that enhance operational efficiency. A significant benefit of using triplex pumps is their ability to maintain constant pressure, which is essential for processes that require precise fluid delivery. According to a report by the American Society of Mechanical Engineers (ASME), consistent pressure in fluid systems can improve overall system performance by up to 15%. This reliability is crucial in industries like oil and gas, where fluctuations in flow can lead to downtime and increased operational costs.

Moreover, the design of triplex pumps allows for reduced maintenance requirements compared to traditional pumps. This is largely due to the lower pulsation and vibration levels they produce, which minimizes wear and tear on the equipment. A study conducted by the International Pump Manufacturers Association (IPMA) found that facilities using triplex pumps experienced a 30% reduction in maintenance costs over a five-year period. Additionally, their efficient design can lead to energy savings of approximately 20%, making them a sustainable choice for fluid management in various industrial applications.

Best Practices for Maintaining Triplex Pumps for Optimal Performance

Maintaining triplex pumps is essential for achieving optimal performance in industrial fluid management. Regular inspections play a crucial role in identifying potential issues before they escalate. Operators should check for any signs of wear or damage to the pump components, including pistons, valves, and seals, as these parts directly impact the pump's efficiency. Implementing a predetermined maintenance schedule ensures that all parts receive necessary attention, reducing the risk of unexpected failures that could disrupt operations.

Another best practice involves monitoring the lubrication system. Proper lubrication minimizes friction and heat buildup, which can lead to premature wear. It is important to use the manufacturer-recommended lubricant and to maintain adequate levels at all times. Additionally, operators should be vigilant about monitoring the fluid levels and quality; contaminated fluids can impair pump performance and reduce the lifespan of the equipment. By adopting these maintenance strategies, industries can unlock the full potential of triplex pumps, ensuring consistent efficiency and reliability in fluid management processes.

Future Trends: Innovations in Triplex Pump Technology for Industry

As we look toward the future of industrial fluid management, innovations in triplex pump technology are set to redefine efficiency standards in various sectors. Recent reports from the Fluid Power Journal indicate that advancements in materials and design have led to a 20% increase in pumping efficiency over traditional models. This is particularly significant in industries where precision and reliability are critical, such as oil and gas and chemical processing.

One of the most exciting trends is the integration of smart technology within triplex pumps. By incorporating IoT capabilities, operators can monitor performance in real-time, leading to proactive maintenance and reduced downtime. According to a recent study by the Industrial Pump Association, companies utilizing smart triplex pumps experienced a 15% decrease in maintenance costs.

Tips: When considering an upgrade to triplex pumps, evaluate the specific operational needs of your facility. Ensure that your new pumps can integrate with existing systems, and invest in training for your team to maximize the benefits of cutting-edge technology. Additionally, staying informed about emerging trends can help you leverage these innovations effectively, ensuring your operations remain competitive.