Understanding the Mechanics of Piston Pumps: A Deep Dive into Their Applications and Innovations

Piston pumps are pivotal in various industrial applications, serving essential roles in sectors ranging from oil and gas to manufacturing. According to a recent report by MarketsandMarkets, the global piston pump market is projected to reach $6.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.1% due to increasing demand for efficient fluid handling systems. This growth highlights not only the versatility of piston pumps but also their technical innovations that enhance performance and operational efficiency.

Industry expert Dr. Emily Chen, a leading authority on hydraulic systems, remarks, "The evolution of piston pump technology is driving efficiencies that businesses rely on for operational excellence." Her insights underscore the significant advancements in piston pump design and functionality that are addressing the modern challenges faced in fluid transfer and pressure control processes. As industries strive for sustainability and cost-effectiveness, understanding the mechanics of piston pumps becomes essential. This article delves into their operational intricacies, cutting-edge innovations, and the diverse applications that are reshaping the landscape of fluid management today.

Understanding the Basic Principles of Piston Pump Operation and Functionality

Piston pumps operate based on the principle of positive displacement, where a

piston moves back and forth within a cylindrical chamber to create suction and discharge fluid. This mechanism allows

piston pumps to maintain a consistent flow rate regardless of pressure changes in the system, making them highly

reliable for various applications. According to a report by MarketsandMarkets, the

global piston pump market is expected to reach approximately $8.5 billion by 2026,

driven by their efficiency in sectors such as oil and gas, chemical processing, and water treatment.

In hydraulic applications, piston pumps are particularly valued for their ability to generate high pressure,

often exceeding 10,000 psi. This high-pressure output makes them ideal for applications

that require precise control, such as in hydraulic machinery and fueling systems for aircraft. Furthermore,

innovations in materials and design, such as the use of wear-resistant coatings and advanced sealing technologies,

have significantly enhanced their durability and performance. A recent study featured in the Journal of Fluid Engineering

highlights that these advancements can lead to a 20% increase in operational efficiency

compared to traditional models.

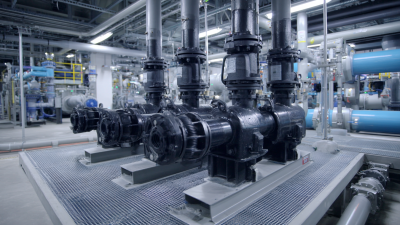

Identifying Key Applications of Piston Pumps in Various Industries with Statistical Insights

Piston pumps are essential components across various industries, thanks to their ability to provide high pressure and efficient fluid transfer. In the oil and gas sector, they are widely utilized for hydraulic fracturing and crude oil transportation. According to recent statistics, the global market for piston pumps in this industry is expected to grow by 5% annually, reflecting a rising demand for efficient extraction methods. Furthermore, the water treatment industry relies on piston pumps for carbon dioxide injection and chemical dosing, improving processes with precision.

In the manufacturing sector, piston pumps are pivotal in applications such as plastic molding and metal forming. Their ability to handle high viscosity fluids makes them ideal for transferring grease and oils used in machinery. Market insights indicate that the demand for piston pumps in manufacturing is expected to see an upward trend, driven by advancements in automation and the need for meticulous process control. These statistics highlight the pivotal role piston pumps play, underlining their importance in enhancing efficiency and innovation across different industrial verticals.

Exploring Recent Innovations in Piston Pump Technology and Their Impacts on Efficiency

Recent innovations in piston pump technology have significantly enhanced their efficiency and functionality across various applications. One of the most notable advancements is the integration of smart technology, which allows for real-time monitoring and optimization of pump performance. This capability enables users to adjust parameters dynamically, leading to reduced energy consumption and prolonged equipment life. Manufacturers are increasingly using advanced materials and coatings that resist wear and corrosion, further increasing durability and reducing maintenance costs.

Additionally, innovative designs such as variable displacement piston pumps offer greater flexibility and adaptability to different operational requirements. These pumps can adjust their output based on system demand, optimizing performance and minimizing energy waste. Furthermore, the incorporation of improved hydraulic fluids and seal technologies has led to enhanced sealing capabilities, reducing the likelihood of leaks and increasing the overall efficiency of the system.

These advancements not only improve the reliability of piston pumps but also contribute to a more sustainable and eco-friendly approach in industries reliant on fluid power systems.

Analyzing the Advantages of Piston Pumps Over Other Pump Types with Performance Data

Piston pumps are increasingly recognized for their superior performance in various industrial applications, particularly when compared to other pump types. One of the key advantages of piston pumps is their ability to handle high-pressure conditions, making them ideal for demanding environments, such as mining and chemical processing. This capability not only enhances efficiency but also reduces downtime, as these pumps are less likely to fail under stress compared to centrifugal pumps. Performance data shows that piston pumps can deliver precise flow rates, which is critical for operations requiring accurate measurement, such as in the metering pumps market, projected to reach USD 7.5 billion by 2034.

Moreover, the growing mining sector significantly contributes to the demand for piston pumps. As indicated by the market projections, the mining pump market is valued at USD 7.1 billion in 2024 and is expected to grow at a CAGR of 4.9% through 2034. The robustness and reliability of piston pumps make them a preferred choice in extracting minerals and other resources, where they are tasked with moving abrasive slurries and other challenging materials. The continuous innovations in piston pump technology not only enhance their performance but also expand their applications, adding to their competitive edge in the market.

Analysis of Piston Pumps Performance Compared to Other Pump Types

Assessing the Future Trends in Piston Pump Development and Market Growth Projections

The future trends in piston pump development are shaped by a convergence of technological innovation and increasing market demands. As industries strive for greater efficiency and sustainability, piston pumps are being designed to incorporate advanced materials and components that enhance their performance. Innovations such as smart sensors and automation are also becoming prominent, allowing for real-time monitoring and optimization of pump operations. These advancements not only improve reliability but also reduce maintenance costs, positioning piston pumps as critical components in various applications from industrial manufacturing to renewable energy sectors.

Market growth projections for piston pumps reflect a robust demand driven by the expansion of sectors such as oil and gas, pharmaceuticals, and food processing. The emphasis on energy efficiency and environmentally friendly technologies is pushing manufacturers to develop more sophisticated and versatile piston pump designs. Furthermore, as the global push for sustainable practices continues, we can expect increased investments in piston pump research and development. This focus on innovation is likely to generate new applications and expand the market reach, making piston pumps a pivotal player in the future of fluid management solutions.

Understanding the Mechanics of Piston Pumps: A Deep Dive into Their Applications and Innovations

| Application | Industry | Innovation Trend | Market Growth Projection (2024-2029) |

|---|---|---|---|

| Hydraulic Systems | Construction | Smart Sensors Integration | 8% CAGR |

| Water Treatment | Environmental | Energy Efficiency Enhancements | 7% CAGR |

| Food Processing | Food & Beverage | Hygienic Design Innovations | 6% CAGR |

| Chemical Injection | Chemical Processing | Automation and Control Systems | 9% CAGR |

| Fuel Transfer | Energy | Low-Emission Technologies | 5% CAGR |

Related Posts

-

The Ultimate Guide to Choosing the Right Hose Reel for Your Garden Setup

-

Transform Your Gardening Experience: The Ultimate Guide to Choosing a Heavy Duty Garden Hose Reel

-

Unlock the Power: Essential Tips for Choosing the Best Power Washer Pump for Your Needs

-

Revolutionize Your Cleaning Routine with a Soft Wash System Kit for Effective Surface Care

-

Unlocking Efficiency: How Triplex Pumps Transform Industrial Fluid Management

-

Understanding the Power of Diaphragm Water Pumps in Modern Irrigation Systems