10 Essential Tips for Choosing the Right Relief Valve for Your System?

Choosing the right relief valve is critical for system safety and efficiency. Paul Anderson, a renowned expert in fluid dynamics, once said, “Selecting the right relief valve can prevent catastrophic failures.” Relief valves serve as vital components in regulating pressure within various systems. A small mistake in your choice can lead to significant safety hazards.

Many factors come into play when selecting a relief valve. You must consider factors like pressure rating, media compatibility, and the specific application needs. Each decision should be weighed carefully. Even experienced professionals sometimes overlook these details, leading to costly mistakes. Understanding how each type of relief valve operates is essential for making an informed choice.

In the complex world of industrial systems, the right relief valve can make a tangible difference. It’s not merely a mechanical component; it is about safeguarding people and equipment. Take your time, do thorough research, and consult with experts when necessary. Your choice matters more than it seems.

Understanding the Function of Relief Valves in Your System

Relief valves play a crucial role in various systems. They are designed to protect equipment from overpressure. When the pressure exceeds a preset limit, the valve opens. This prevents potential damage or catastrophic failures. Understanding their function is essential for safety and efficiency.

In many systems, pressure fluctuations are common. Relief valves help maintain stability. For example, they can relieve excess pressure in a steam system. This action ensures smooth operation and prevents risks. However, choosing the right relief valve can be challenging. Factors such as fluid type, pressure rating, and installation location must be considered.

Sometimes, users underestimate the significance of sizing. An incorrectly sized valve may fail to open when needed. Alternatively, a valve that is too large may cause unnecessary cycling. Each scenario requires careful evaluation and reflection. Consider the specifics of your system and its components.

Identifying the Key Specifications for Your Relief Valve Selection

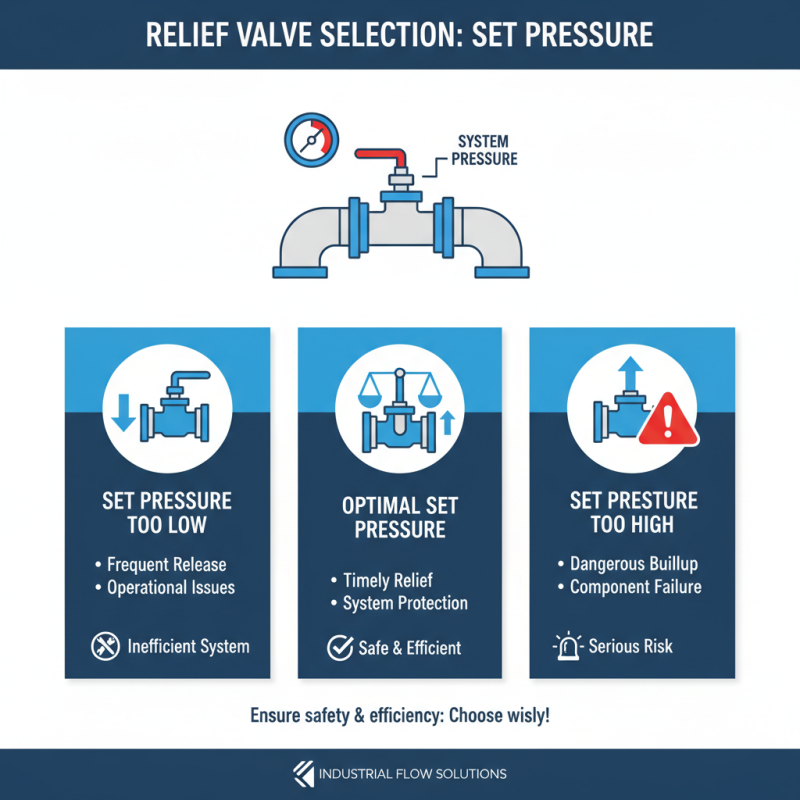

When selecting the right relief valve for your system, understanding key specifications is crucial. Start with the valve's set pressure. This determines when the valve will open to relieve excess pressure. If it's set too low, it may frequently release, causing unnecessary operation issues. If it's too high, it could lead to dangerous pressure build-up.

Next, examine the valve's flow capacity. This is often measured in terms of the valve’s Cv rating. A higher Cv rating allows for more fluid to pass through when the valve is open. However, choosing an excessively high Cv can lead to a loss of system performance and efficiency. Balancing these parameters is vital.

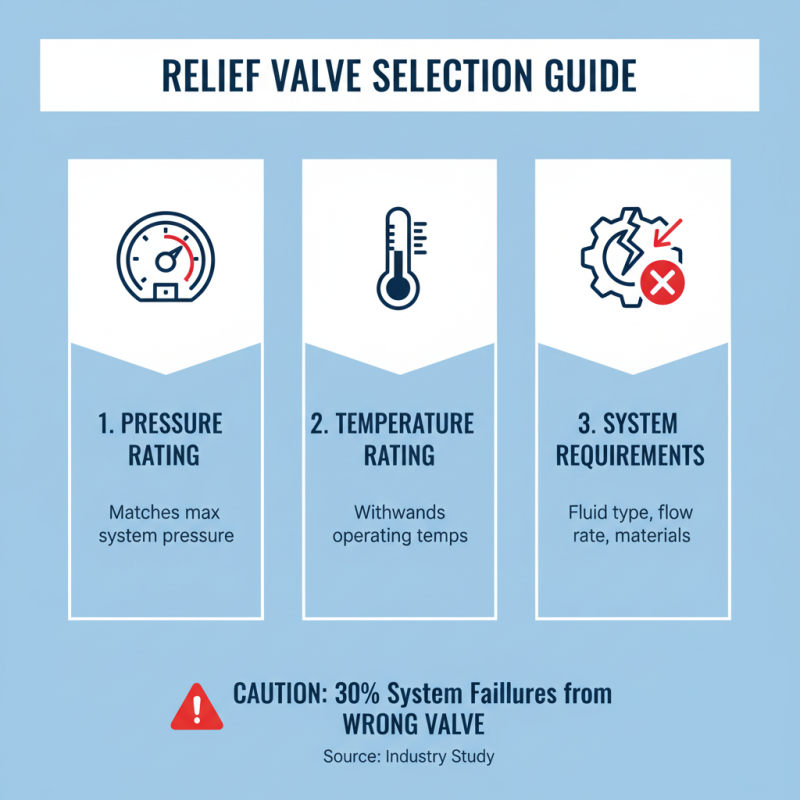

Another essential specification is the temperature range. Ensure the valve can withstand your system's operating conditions. If temperatures exceed the valve's limits, it can lead to catastrophic failures. Furthermore, consider the materials used in the valve construction. The wrong material may corrode, leak, or fail under stress. Each choice must fit perfectly with your system's unique requirements.

Evaluating Material Compatibility for Durability and Performance

When selecting a relief valve, material compatibility is crucial for ensuring durability and performance. Different materials have varying resistance to temperature and pressure changes. For instance, stainless steel offers excellent corrosion resistance, making it suitable for harsh environments. However, it may not perform well in applications involving aggressive chemicals.

Consider the operational conditions your system faces. A recent report noted that nearly 30% of valve failures are linked to improper material selection. This highlights the importance of matching the valve material with the medium it will encounter. For instance, using brass valves in acidic environments can lead to rapid degradation.

Test your material choices under real conditions. The performance of materials can change over time. Regular evaluations ensure that the selected material continues to meet the system’s demands. Remember, material compatibility goes beyond initial selection. It’s an ongoing process that requires reflection and adjustment based on performance data and environmental factors. Aim for a proactive approach to avoid costly failures down the line.

Assessing Pressure and Temperature Ratings for Safety and Efficiency

Choosing the right relief valve demands careful consideration of pressure and temperature ratings. According to a recent industry study, improper valve selection causes 30% of system failures. Understanding your system's specific requirements is crucial.

Knowing the maximum allowable pressure (MAP) helps prevent potential safety risks. The valve must handle extreme conditions without failing. Reports indicate that valves rated incorrectly can lead to leaks or ruptures. Temperature ratings are equally important. A valve operating outside its temperature range can degrade fast, undermining its function.

Regularly updating your system's pressure and temperature specifications is essential. Many users overlook this, resulting in inefficient operations. When assessing your system, prioritize data accuracy. Revisit your valve options against current standards. A deeper understanding of potential risks leads to better choices and improved safety.

Exploring Installation and Maintenance Considerations for Longevity

When installing a relief valve, consider your system's specifications carefully. Ensure the selected valve meets the pressure and flow requirements. A mismatch can lead to serious issues, such as leaks or system failures. Understanding the application is key. For example, if liquids or gases vary in temperature, the valve material should withstand those conditions.

Routine maintenance is crucial. Inspect the valve regularly for signs of wear and tear. If left unchecked, minor issues can escalate quickly. Keep an eye on the sealing surfaces; they can degrade over time. A forgotten valve might lead to catastrophic failures or costly repairs. Record your maintenance checks. This simple act can reveal patterns that help in adjusting your care strategy.

Installation tips often emphasize alignment and support. An improperly aligned valve can disrupt system pressure balance. Ensure the valve is supported adequately to avoid undue stress. Sometimes, a simple adjustment can make a noticeable difference. If you experience frequent issues, consider reviewing installation practices. Reflecting on past challenges often leads to improved strategies for the future.

Pressure Settings of Various Relief Valve Types

Related Posts

-

2025 Guide: How to Choose the Best Soft Wash Pump for Effective Cleaning

-

The Ultimate Guide to Choosing the Right Hose Reel for Your Garden Setup

-

10 Essential Tips for Choosing the Right Power Washer Pump for Optimal Performance

-

Top 10 Tips for Choosing the Right Electric Diaphragm Pump for Your Needs

-

Top 5 Heavy Duty Garden Hose Reels that Last Longer and Save You Time

-

2026 Best Hose Reel Options for Efficient Gardening and Outdoor Use?