10 Essential Tips for Choosing the Right Diaphragm Water Pump for Your Needs

When it comes to selecting the right diaphragm water pump for your specific needs, understanding the key factors that contribute to its performance and suitability is essential. Diaphragm water pumps are versatile devices widely used for various applications, from agricultural irrigation to fluid transfer in industrial settings. Their unique design allows for efficient handling of fluids, including those with solids or abrasive components, making them preferred choices in many scenarios.

Choosing a diaphragm water pump involves consideration of several critical factors such as flow rate, pressure requirements, and the nature of the fluids being pumped. This decision-making process can be overwhelming without the right guidance. Therefore, this article aims to provide you with ten essential tips that will not only simplify your selection process but also ensure that you choose a diaphragm water pump that meets your expectations and requirements. By following these guidelines, you can ensure optimal performance and longevity of the equipment while achieving your desired outcomes in various applications.

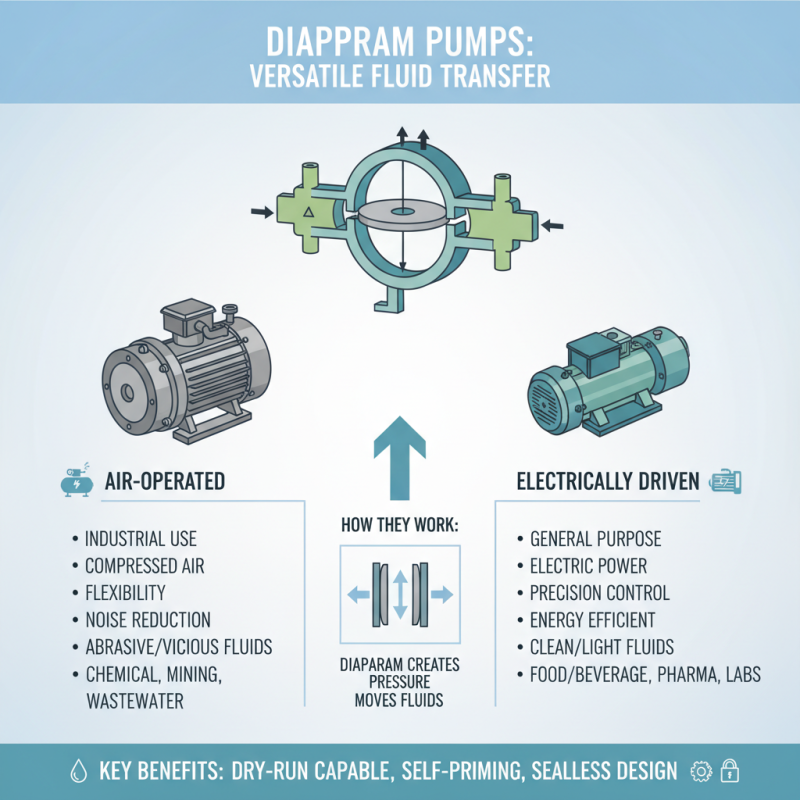

Understanding Diaphragm Pumps: Types and Applications

Diaphragm pumps are versatile devices that utilize a diaphragm to create pressure and move fluids, making them suitable for various applications. There are two primary types of diaphragm pumps: air-operated and electrically driven. Air-operated diaphragm pumps are typically used in industrial settings where compressed air is accessible, providing flexibility and noise reduction. They are ideal for handling abrasive and viscous fluids due to their robust design, making them a preferred choice in chemical processing, mining, and wastewater management.

On the other hand, electrically driven diaphragm pumps offer a different set of advantages. These pumps are well-suited for applications requiring precision and control, such as laboratory settings and food processing. They can handle a wide range of fluids and are particularly effective for low-flow, high-pressure applications. Understanding the specific application requirements—such as fluid type, viscosity, and environmental conditions—will help ensure the right diaphragm pump is chosen, ultimately leading to improved efficiency and longevity in performance.

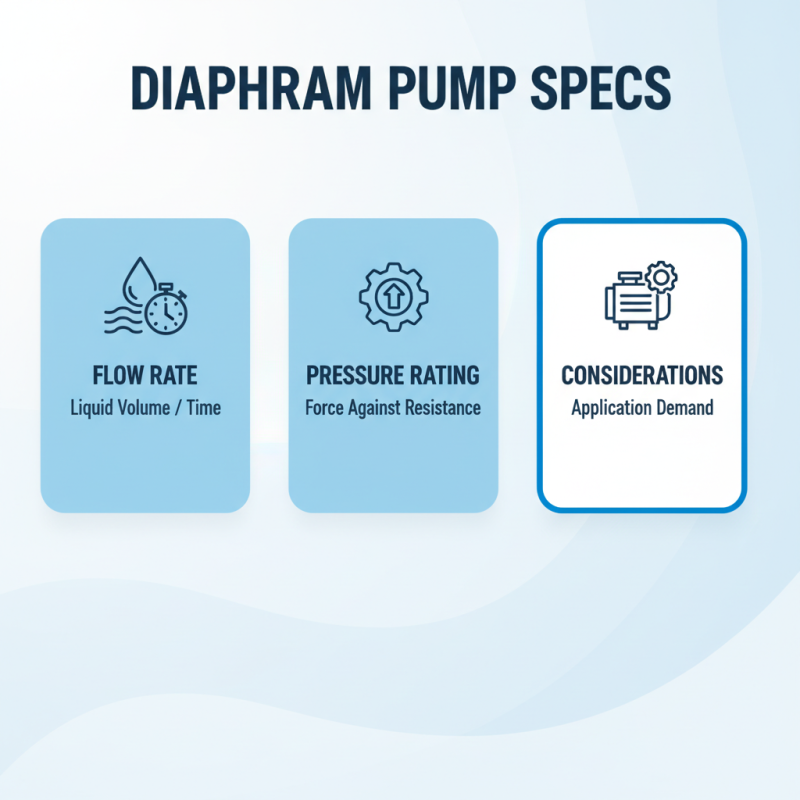

Key Specifications to Consider for Diaphragm Water Pumps

When selecting the right diaphragm water pump for your needs, it's crucial to consider several key specifications that can significantly impact performance and efficiency. Flow rate is one of the most fundamental factors; it determines how much liquid the pump can handle over time. Ensure that the selected pump can meet the demands of your application without overworking the system. Additionally, consider the pump's pressure rating, as this influences its ability to move fluids effectively against resistance.

Another essential tip is to evaluate the material compatibility. Diaphragm pumps are often used for various fluids, including chemicals, so selecting a pump made from materials that withstand the specific substances is critical. This helps prevent corrosion and prolongs the pump's life. Furthermore, pay attention to the power source; choose between electric or pneumatic options based on your operational environment and available resources. By focusing on these specifications, you can make a more informed decision that meets both your operational needs and budget constraints.

Evaluating Pump Performance: Flow Rate and Pressure Requirements

When evaluating pump performance, the most critical factors to consider are flow rate and pressure requirements. Flow rate determines how much fluid can be moved over a specific timeframe, which is crucial for applications ranging from agricultural irrigation to industrial fluid management. According to industry reports, pumps that operate efficiently are often capable of delivering flow rates between 10 and 100 gallons per minute (GPM) while maintaining optimal pressure levels. For instance, in mixed flow pump designs, high flow rates combined with moderate head pressures make them an ideal option for various pumping station installations, emphasizing the necessity of balancing these parameters for effective operation.

In addition, understanding the pressure requirements is essential for ensuring that the pump can sustain the system’s demands under varying load conditions. Recent advancements in pump technology, such as the development of magnetic and hydrodynamically suspended blood pumps, highlight the importance of achieving stable pressure output while minimizing vibrations and noise levels. Techniques like acoustic and vibration analysis at high frequencies have shown to be sensitive indicators for cavitation, which can severely affect pump performance. Utilizing tools to assess these factors can streamline pump selection, ensuring that users choose devices that not only meet their specific needs but also enhance overall system efficiency. By combining flow rate and pressure considerations with modern evaluation techniques, users can make informed decisions that lead to improved operational outcomes.

10 Essential Tips for Choosing the Right Diaphragm Water Pump for Your Needs

| Pump Model | Flow Rate (GPM) | Max Pressure (PSI) | Weight (lbs) | Power Requirement (HP) |

|---|---|---|---|---|

| Model A | 3.5 | 60 | 12 | 1.0 |

| Model B | 5.0 | 80 | 15 | 1.5 |

| Model C | 7.0 | 100 | 20 | 2.0 |

| Model D | 4.5 | 70 | 14 | 1.2 |

| Model E | 6.0 | 90 | 16 | 1.8 |

Material Selection: Impact on Lifespan and Chemical Compatibility

When selecting a diaphragm water pump, material selection plays a crucial role in determining both the lifespan of the pump and its compatibility with various chemicals. Different materials, such as plastic, aluminum, and stainless steel, each present unique advantages and disadvantages based on the specific application. For instance, plastic pumps are often lightweight and resistant to corrosion, making them suitable for pumping harsh chemicals. However, they may not perform well under high pressure compared to their metal counterparts.

Moreover, chemical compatibility cannot be overlooked. It’s essential to match the pump material with the fluid being transported to prevent degradation and ensure optimal performance. Stainless steel, for example, offers superior strength and durability, making it ideal for handling abrasive or corrosive substances. On the other hand, rubber diaphragms may be more flexible and adaptable, but they can wear out quickly when exposed to certain chemicals. Understanding these material implications helps to make an informed decision that maximizes the operational efficiency and longevity of the diaphragm water pump.

Maintenance Tips to Extend the Life of Your Diaphragm Pump

To ensure the longevity of your diaphragm water pump, regular maintenance is crucial. One of the most important maintenance tips is to conduct routine inspections. Check for any signs of wear and tear, especially on the diaphragm and seal. Regularly clean the pump and its components to prevent any buildup of debris or sediment that could impede performance. Using clean, filtered water can significantly reduce the chances of clogging and ensure smoother operation.

Additionally, lubrication plays a critical role in extending the life of your diaphragm pump. Make sure to use the manufacturer-recommended lubricants and apply them according to the maintenance schedule. Over time, seals can dry out, leading to leaks and reduced efficiency; therefore, replacing worn seals promptly is essential. Lastly, consider keeping a maintenance log to track any issues or repairs done, as this can help in anticipating future problems and ensuring your diaphragm pump operates at peak performance for years to come.

10 Essential Tips for Choosing the Right Diaphragm Water Pump

The chart below illustrates the key factors to consider when selecting a diaphragm water pump, including flow rate, pressure, material durability, maintenance frequency, and energy efficiency. These metrics are essential for ensuring the longevity and effectiveness of your diaphragm pump.

Related Posts

-

Understanding the Power of Diaphragm Water Pumps in Modern Irrigation Systems

-

The Ultimate Guide to Choosing the Right Hose Reel for Your Garden Setup

-

10 Essential Tips for Choosing the Right Power Washer Pump for Optimal Performance

-

Transform Your Cleaning Routine: The Ultimate Guide to Soft Wash System Kits for Effective Home Maintenance

-

Maximizing Efficiency with Industrial Water Hose Reels for Optimal Fluid Management in Manufacturing

-

2025 Guide: How to Choose the Best Soft Wash Pump for Effective Cleaning