Top Benefits of Using Pneumatic Diaphragm Pumps in 2025 Applications

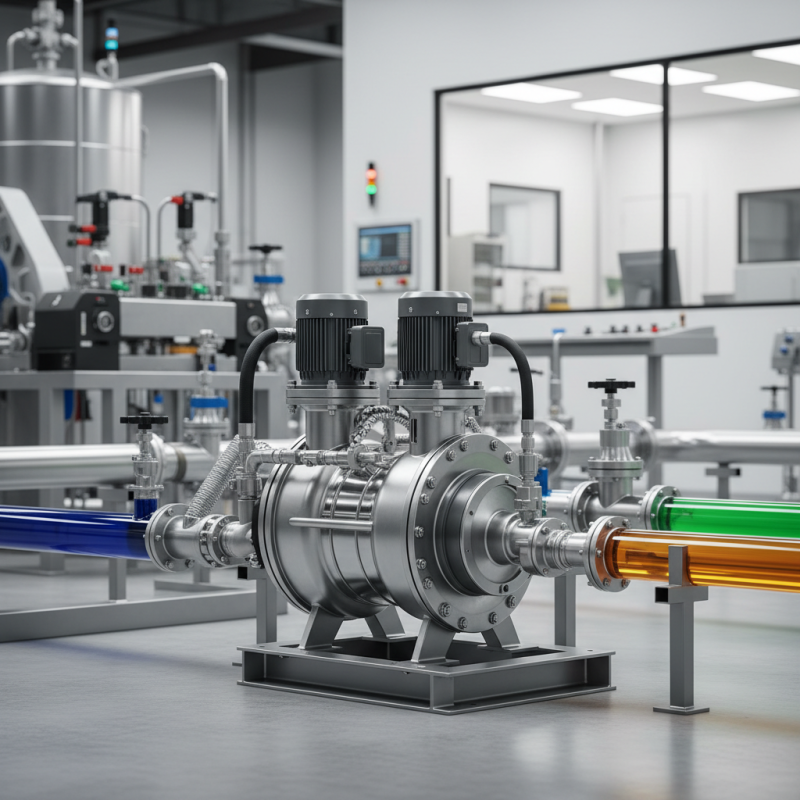

The increasing complexity of industrial processes in 2025 has prompted a reevaluation of equipment used for fluid transfer. Among the various options available, pneumatic diaphragm pumps stand out as a versatile and efficient solution that caters to a wide range of applications. These pumps utilize compressed air to create a pressure differential, allowing them to move liquids and slurries with remarkable precision and reliability. With their robust design and ability to handle a diverse array of fluids, pneumatic diaphragm pumps are gaining traction across numerous industries.

One of the most notable benefits of using pneumatic diaphragm pumps is their inherent safety features. Unlike electrically powered pumps, these pneumatic systems significantly reduce the risk of electrical sparks, making them ideal for handling flammable or hazardous materials. Furthermore, their simple construction contributes to reduced maintenance costs and extended lifespan, ensuring they remain a cost-effective choice for businesses looking to optimize their operations. As industries continue to prioritize efficiency and sustainability, the adoption of pneumatic diaphragm pumps is expected to rise, positioning them as a key component in modern fluid management strategies. By exploring the top benefits of these pumps, businesses can better understand how to leverage their capabilities for improved operational performance in 2025 and beyond.

Key Features of Pneumatic Diaphragm Pumps in Modern Applications

Pneumatic diaphragm pumps have become increasingly essential in various modern applications due to their unique features, enhancing operational efficiency and reliability. One of the primary characteristics of these pumps is their ability to handle a wide range of fluids, including corrosive and viscous substances. According to a report by MarketsandMarkets, the global diaphragm pump market is projected to grow from $1.5 billion in 2020 to $2.3 billion by 2025, highlighting the rising demand for versatile pumping solutions in industries such as chemical processing and water treatment.

Another critical feature of pneumatic diaphragm pumps is their self-priming capability and low maintenance requirements. These pumps operate using compressed air, which eliminates the risk of electrical hazards, making them ideal for hazardous environments. A study published by Research and Markets indicated that the demand for pneumatic pumps in industries focusing on safety and environmental regulations is rising significantly, with an estimated growth rate of 8% annually. This trend reflects a growing awareness of the importance of equipment that can operate efficiently and safely under challenging conditions, leading to improved productivity and lower operational costs.

Top Benefits of Using Pneumatic Diaphragm Pumps in 2025 Applications

| Feature | Description | Benefit |

|---|---|---|

| Self-Priming Capability | Can draw liquid into the pump without needing external assistance. | Increases operational efficiency and reduces downtime. |

| Adjustable Flow Rate | Flow rate can be easily adjusted to meet specific application needs. | Enhances flexibility for diverse applications in various industries. |

| Durable Construction | Built with robust materials to withstand harsh conditions. | Minimizes maintenance costs and extends service life. |

| No Electricity Needed | Operates using compressed air instead of electrical power. | Safer in flammable environments and reduces electricity costs. |

| Versatile Material Handling | Can handle a wide range of liquids including corrosive and viscous fluids. | Ideal for various industrial applications, enhancing usability. |

| Low Shear Stress | Gentle pumping action minimizes damage to sensitive materials. | Ensures product integrity, especially in food and pharmaceutical industries. |

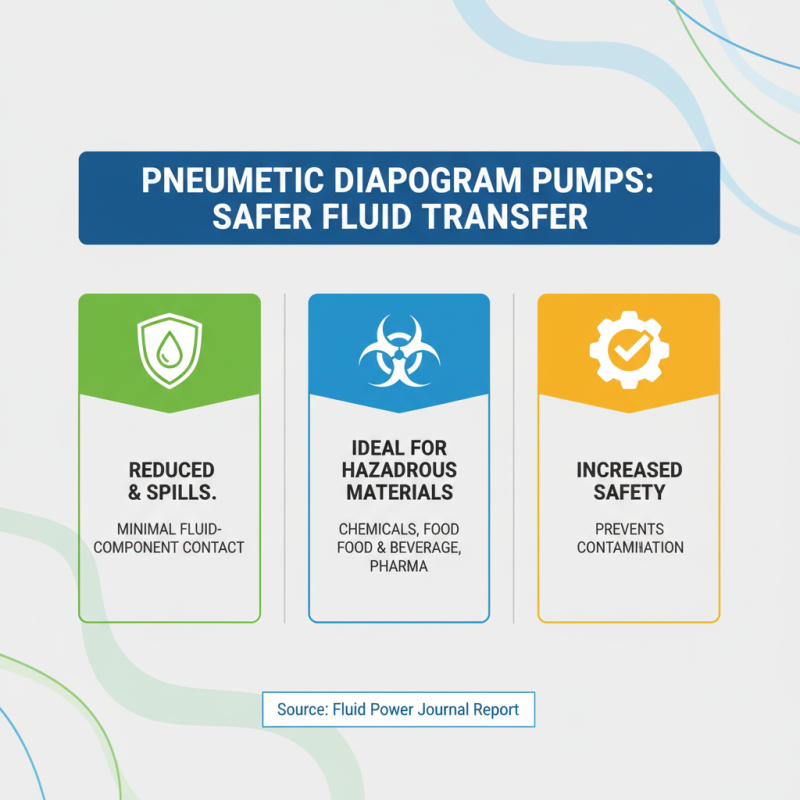

Advantages of Pneumatic Diaphragm Pumps Over Traditional Pumping Systems

Pneumatic diaphragm pumps have become increasingly popular in various applications due to their numerous advantages over traditional pumping systems. One significant benefit is that they are inherently safe for handling hazardous materials. A report published by the Fluid Power Journal indicates that pneumatic pumps significantly reduce the risk of leaks and spills, thanks to their design which minimizes contact between the fluid and pump components. This makes them ideal for industries such as chemicals, food and beverage, and pharmaceuticals, where contamination and safety are major concerns.

Additionally, pneumatic diaphragm pumps are known for their versatility and efficiency. A study by the Global Pumps and Pumping Systems Market highlighted that these pumps can handle a wide range of viscosities and solids without the need for extensive modifications or specialized components. Their ability to operate dry without damage and to self-prime makes them a cost-effective solution for various applications. The report states that industries utilizing pneumatic diaphragm pumps have reported up to a 30% increase in operational efficiency, mainly due to reduced maintenance downtime and improved reliability compared to traditional pump systems. This efficiency aligns with the increasing demand for sustainable practices, as businesses seek to minimize operational costs while maximizing output.

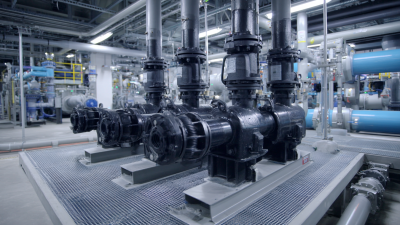

Industries Benefiting Most from Pneumatic Diaphragm Pump Technology

Pneumatic diaphragm pump technology is increasingly gaining traction in various industries due to its efficiency and versatility. In 2025, sectors such as pharmaceuticals, food and beverage, and wastewater treatment are expected to benefit significantly from this pumping solution. According to a recent industry report by MarketsandMarkets, the global diaphragm pump market is projected to reach USD 4.1 billion by 2026, growing at a CAGR of over 7% from 2021. This growth can be attributed to the pumps' ability to handle viscous and abrasive materials without compromising reliability.

The pharmaceutical industry, in particular, relies on pneumatic diaphragm pumps for their hygienic properties. These pumps minimize contamination risks, which is critical in drug manufacturing processes. Additionally, the food and beverage sector appreciates the sanitary design of diaphragm pumps, enabling them to comply with stringent regulations while ensuring the integrity of the products they handle. Wastewater treatment facilities benefit from diaphragm pumps as they efficiently move sludge and other heavy materials.

**Tip:** When selecting a pneumatic diaphragm pump for your application, consider the material compatibility and flow rate specific to your project requirements. Ensuring these pumps meet industry standards can greatly enhance operational efficiency and safety.

**Tip:** Regular maintenance of diaphragm pumps not only prolongs their lifespan but also ensures optimal performance, which is vital for industries with strict quality control measures. Routine inspections can identify potential wear and tear before they lead to costly downtime.

Future Trends in Pneumatic Diaphragm Pump Usage and Development

In 2025, the application of pneumatic diaphragm pumps is expected to grow significantly across various industries, driven by advancements in technology and an increasing focus on sustainability. There is a noticeable trend towards the integration of smart automation and IoT capabilities, allowing for real-time monitoring and control of pump operations. This improved connectivity not only enhances operational efficiency but also aids in predictive maintenance, thereby reducing downtime and operational costs.

Tips: When considering pneumatic diaphragm pumps for future projects, always look for models that offer compatibility with smart technologies. Investing in pumps equipped with sensors can provide crucial data that helps in optimizing performance and minimizing energy consumption.

Moreover, as industries strive for eco-friendly practices, the demand for energy-efficient pneumatic diaphragm pumps will rise. Manufacturers are expected to focus on innovative materials and designs that enhance pump efficiency while minimizing environmental impact. Furthermore, the development of lightweight and durable materials will likely make these pumps even more versatile, expanding their usage in demanding situations such as chemical processing or wastewater management.

Tips: Prioritize energy-efficient models when selecting pneumatic diaphragm pumps. Checking for certifications or energy ratings can guide you in making environmentally friendly choices that also contribute to long-term savings.

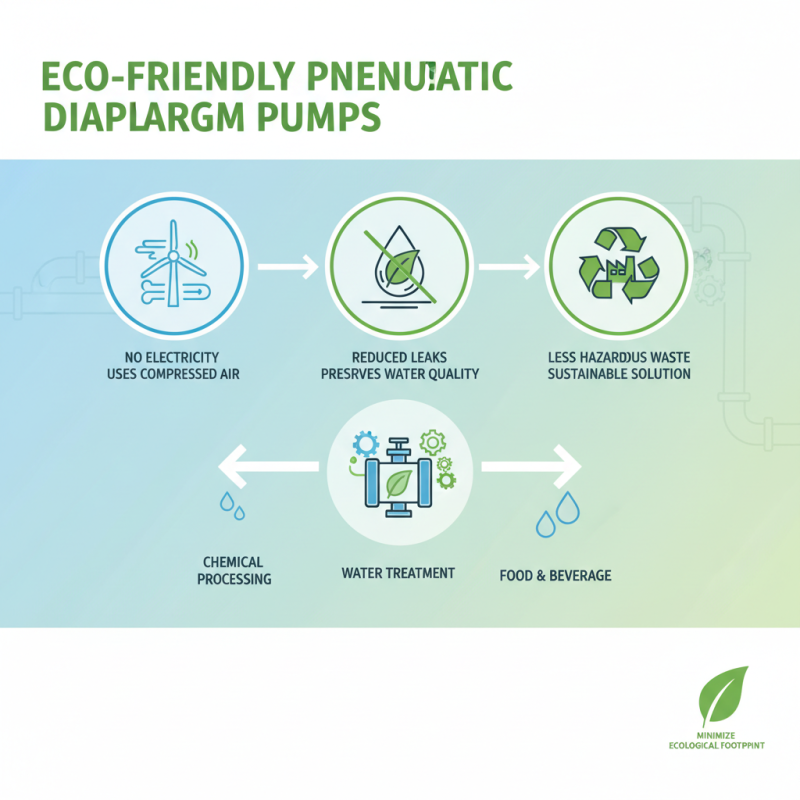

Environmental Impact and Sustainability of Pneumatic Diaphragm Pumps

The environmental impact and sustainability of pneumatic diaphragm pumps are becoming increasingly significant as industries seek to minimize their ecological footprints. These pumps operate using compressed air, which means they do not rely on electricity or hydraulic fluids that can potentially harm the environment. By utilizing air as a power source, pneumatic diaphragm pumps reduce the risk of leaks and contamination, thereby preserving water quality and reducing hazardous waste. This eco-friendly operation aligns with the growing demand for sustainable solutions across various sectors, including chemical processing, water treatment, and food and beverage production.

Moreover, the longevity and reliability of pneumatic diaphragm pumps contribute to their sustainability. These pumps are designed for durability and require minimal maintenance, which translates to fewer resources spent on repairs and replacements. Their ability to handle a wide range of fluids, including corrosive and abrasive materials, without significant wear and tear further enhances their efficiency. By investing in pneumatic diaphragm pumps, industries not only comply with stringent environmental regulations but also support sustainable practices that prioritize resource conservation and reduced emissions. This holistic approach not only benefits the planet but also promotes a more sustainable future for industrial operations.

Related Posts

-

Understanding the Power of Diaphragm Water Pumps in Modern Irrigation Systems

-

10 Essential Tips for Choosing the Right Diaphragm Water Pump for Your Needs

-

Understanding the Mechanics of Piston Pumps: A Deep Dive into Their Applications and Innovations

-

2025 Guide: How to Choose the Best Soft Wash Pump for Effective Cleaning

-

Unlocking Efficiency: How Triplex Pumps Transform Industrial Fluid Management

-

2025 Top 10 Diaphragm Pumps: Unmatched Performance and Reliability for All Industries